Race Car engineering

The 2014 Formula One season marks the biggest change in regulations in the sports history and the W05 is the answer to the changes from Mercedes.

The initial engineering conversations between the teams at Brackley and Brixworth around both the regulations and potential solutions date back to late 2010. Since mid-2011, when the rules for the new V6 Hybrid Power Unit were officially published, Mercedes-Benz claims that it has taken a fully integrated approach to every major performance decision with a clear-sighted focus on maximising overall car performance.

Ta med HD'n till sjöss...

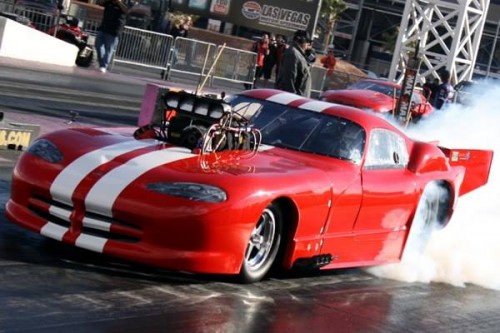

SRT experience

Ride along as SRT Motorsports driver Jonathan Bomarito takes to the streets in

SRT's 640hp, V-10 -Viper GTS

klicka på länken

Utväxling och bättre grepp?

Om du behöver mera ax eller bättre grepp i kurvorna (främst på bana) så finns det mycket info och godis här...

Welcome to UNITRAX!

For over 27 years, UNITRAX has striven to be one of the best and most trusted drivetrain parts and service centers in the U.S.A.

Our extensive inventory of differential, driveline and performance parts allow us to serve our customers promptly and professionally.

UNITRAX is staffed by the most conscientious and experienced mechanics and parts personnel you will find. We are committed to providing our customers with the highest quality parts and service at very competitive prices.

We are proud to distribute and install parts from only the most reliable and trusted companies in the drivetrain industry. Our product line includes:

Dana Spicer, American Axle, Timken, Gear Vendors, Motive Gear, Transfer Flow, Eaton, Neapco, Federal Mogul, OS Giken, Wavetrac, US Gear, Superior Axle & Gear, Schaeffer's and Synergyn Lubricants.

UNITRAX looks forward to serving your differential, driveline, overdrive, fuel system and performance needs.

Ändlös bromsande...

DoDge Viper Hisstory..

Besides the new roof the GTS included such exciting features as roll-up side windows and exterior door handles. Also, the exhaust was rerouted out the back to produce a significantly more pleasing sound and output of the significantly updated 8.0-liter V10 swelled up to 450 hp. Also aboard for the first time were OBD-II emissions controls, aluminum links in the suspension system, dual front airbags and a lighter-weight frame.

That rear exit exhaust also made it to the 1996 RT/10 roadster, which was enough to bump output of its V10 to 415 hp. The roadster also got an improved optional fabric top with better weather sealing.

A production Viper GTS paced the 1996 Indianapolis 500, setting up even more good news for 1996 as the updated 450-hp V10.

The first Viper concept debuted at the 1989 NAIAS, followed by prototypes; the late-1989 VM01 was powered by the 360 V8, but a V10 was already planned. The early-1990 VM02 was powered by the 8-liter V10. The original V10 was reportedly built with the involvement of Lambourghini, which was partly owned by Chrysler at the time; the basic engineering was of course Chrysler’s, since it was based on the venerable 360, but Lambourghini worked on the cooling system, crankshaft balance, weight reduction, and fine tuning; the Italian automaker’s expertise in aluminum was also tapped, since the Viper had an aluminum block to save roughly 150 pounds of weight. Unique features of the Viper version of the V-10, versus the truck engine, included a low-profile cross-ram intake with dual throttle bodies, the manifolds, oil pan, heads, and accessory drive; the compression ratio was raised, the pistons lightened, the maximum engine speed increased, the valves enlarged, the rods and crank strengthened. In the end, few components were shared with the truck engine.

The 2008 Viper had similar consultations from McLaren Performance (not to be confusing with the McLaren racing people who work with Mercedes).

The Viper, at its introduction to the public, was intended to be two things to the corporation. The public version was that Chrysler needed a halo car to show they were still the best at building a low cost vehicle of any type and beating the old Shelby Cobra 0-100-0 times was a showman's way of achieving just that. Privately (and more importantly), within the corporation, the Viper was a production technique testbed- to see if the corporation really could develop new methods of manufacture and assembly to lower the cost of a vehicle. It was originally intended to be killed off and a totally different vehicle replace it in the 1997 model year.

Team Viper's primary goal was a vehicle that concentrated on performance above all else. Their benchmark: to go from 0 to 100 back to 0 in under 15 seconds.

The first result was a show car, which appeared on January 4, 1989 at the North American International Auto Show in Detroit to test public reaction; orders began to flow before the show ended, and the "go" was given.

Chrysler decided to use the Viper RT/10 to test its new platform team concept, taken from Honda's process. An independent cross-functional team was created, making its own rules and creating its own supplier base. The team leader sifted through scores of volunteers to find appropriate people. Team Viper began three years of intensive, often around-the-clock operations that stretched from Italy, where the aluminum engine block was perfected -- to the race tracks at Nelson Ledges and Road Atlanta, where they fine-tuned the chassis and powertrain. Team members worked closely with major automotive suppliers to develop unique components for the Viper RT/10 which would withstand the tremendous stresses associated with high-performance driving. For Chrysler, the Viper itself was considerably less important than the lessons learned in the platform teams, which would soon create in rapid succession the LH (Intrepid), PL (Neon), Clouds (Stratus), new minivans, new Ram, Prowler, and more.

Chassis prototypes, called "mules" in the automotive industry, were developed to study vehicle dynamics. Within a year of Viper's auto show appearance, a V-8-powered mule was being tested. A few months later, a stablemate powered by a cast iron V-10 (presumably from the Ram) joined the test fleet. Finally, in May 1990, Chrysler announced that the Viper would be made with the aluminum V-10; and in May it performed as the official pace car of the Indianapolis 500. Finally, in December of 1991, the first red Viper RT/10 production vehicles rolled off the New Mack Avenue assembly line -- exactly three years after the concept car's 1989 auto show triumph. A second color, black, appeared in 1993, followed in 1994 by yellow and emerald green.

The RT/10 was joined by the Viper GTS in 1996, bringing some refinement to the design, so that it would be one of the world's premier Grand Touring cars rather than a raw racer. The GTS was seen as catering to a broader customer base than the RT/10. While the GTS and the RT/10 look much alike, more than 90 percent of the Coupe was new. Every major part was subjected to scrutiny with telling effect: the GTS with air conditioning weighed nearly 100 pounds less than the 1994 RT/10 without air. Weight reduction changes on both platforms reduced weight by 200 pounds; these included an all-aluminum suspension system and re-engineered frame. For GTS, weight reduction was focused in the engine and cooling system, where over 80 pounds were removed.

By 1998, 9,500 Vipers cruised the world's boulevards and racetracks, building a very strong and extremely enthusiastic owner core. Currently there are more than 1,700 members of the Viper Club of America and 27 Viper Clubs throughout the United States.

What is in a Dodge Viper - and how it is made

Engine

Viper's 8.0-liter engine is the largest and most powerful available today in an American production sports car. Viper GTS Coupe and RT/10 Roadster share the same 450 horsepower (460 in GT2 and ACR models) engine, suspension, brake system and adjustable pedal set.

Air intake is through a cast aluminum manifold with formed tubes, including an integral fuel rail cored in the castings. The dual throttle bodies and bottom-feed high-impedence fuel injectors control fuel flow and mixture. Fuel is fed to the injectors by a sequential multipoint injection system.

The engine's forged aluminum pistons are set in cast iron liners. The aluminum cylinder head features a conventional two valves per cylinder with higher-revving dual valve springs.

While a natural extension of the classic American V-8 (the small-block LA series, to be exact), a number of the V-10's unusual design features were derived from Formula One engines. Among these features are a closed tappet gallery for better intake manifold seating, and a sophisticated internal water flow system which traces its route outside the engine block, inside the cylinder head, around each cylinder and inside each combustion chamber for increased engine cooling.

Spent combustion gasses travel through a stainless steel tubular exhaust manifold, then pass through unique sill-mounted catalytic converters and exit at the center rear.

The six-speed manual transmission was designed to harness Viper's substantial power and match its high-performance expectations. It boasts an electronic reverse lockout feature and first-to-fourth skip-shift for fuel economy.

In developing this engine, Team Viper set out to maintain the simple powertrain design of classic high-performance sports cars -- because simplicity leads to durability, reliability and serviceability.

Classic Construction

Viper's massive V-10 engine is mounted on what is believed to be the stiffest sports car chassis ever built.

The engine is cradled by two massive rectangular-tube frame rails, which turn out at the front bulkhead and continue on down the sides. Positioned between the front bulkhead and the back of the cockpit is a central backbone of smaller rectangular tubes. This is attached at the back to a cage or box which encompasses the rear suspension, a 19-gallon fuel tank, a spare tire, the battery and the trunk.

The fully independent front and rear suspensions feature unequal-length upper and lower "A" arms and coil-over springs made of lightweight, yet strong micro-grain alloy steel. High-performance gas-filled shocks minimize aeration.

The power-assisted rack-and-pinion steering system features positive on-center feel and a fast 16.7:1 steering ratio for quick and responsive maneuvering. Lock to lock is accomplished in a mere 2.4 turns. Viper's turning circle is 40.5 feet and its maximum turning angle is 28 degrees.

Viper's high performance brake system features four-piston front calipers with huge 13" x 1.26" vented rotors up front and 13" x.86 vented rotors at the rear. This system was specially designed to help meet the stated test-track goal of 0-100-0 mph in less than 15 seconds.

Truly massive high performance Michelin Pilot Sport tires created for the Viper are instrumental in translating the car's abundant horsepower and torque to more linear terms. These directional tires, 275/35ZR18 front and 335/30ZR18 rear, are a major factor in Viper's 1g lateral acceleration capability.

The tires are mounted on forged aluminum wheels with Viper logo centers (BBS forged aluminum wheels with chrome Viper Head center caps for the GT2 and ACR models).

Finally, Viper's cooling system consists of a lightweight copper-core radiator and an electronically controlled dual-speed electric fan. A front-mounted engine air-to-oil cooler is also standard.

Assembly & Testing

Each Dodge Viper is hand-assembled at a special Detroit, Michigan facility on Conner Avenue by carefully chosen, skilled UAW workers with over 300 hours of training each.

Each Viper is made up of approximately 50 component modules which are shipped to the Viper facility from locations throughout North America. Stamping, casting, painting and welding take place off-site. Composite body panels arrive already painted. Complete instrument panels are supplied with the gauges tested and set in place. Engines are assembled and tested at a Chrysler engine plant.

The Conner Avenue Assembly Plant has adjacent work stations. Adjustments are made at each work station by individual craftspersons acting as their own inspectors, eliminating traditional repair stations and inspectors. Problems are immediately dealt with, even if they require a discussion with the on-site Team Viper engineer. All procedures are verified by assembly team members, with working team leaders coordinating efforts through craft managers.

The Viper assembly process is as unique as the car itself, even extending to testing procedures. For example, as is the case with race cars, wheel alignment includes adjustment of "bump steer." A special machine is used to align all four wheels off their wheel hubs. In this way, the wheels are moved up and down in their suspension travel and alignment is set in three different positions.

Every Viper is also "roll tested," which involves running the car at speed, in place, on special rollers right at the assembly center while the car is a "hot rolling chassis" minus all body panels. It is driven through all six speeds of its transmissions, up to 90 mph, in order to validate the proper functioning of all systems under actual driving conditions

Göran Malmberg Pantera

Dodge Viper history

SRT Viper GT3

Rejsa försiktigt...

Allt du behöver veta om bromsar ...

Cartek battery Isolator

Flamholc tillbaka

GTS-R -Le Mans 2013

The rich history of the SRT® Viper GTS-R in the 24

Hours of Le Mans.

Many are never able to master the fickle track or taste the sweet champagne that accompanies a win at Le Mans no matter how many times they try. The SRT® Motorsports teams, on the other hand, were quick studies with Viper, claiming a class win at Le Mans in just their third start in 1998.

As an encore, Team Viper won again at Le Mans in 1999 and made it a three-peat in 2000, which ironically marked the last time a factory-backed Viper raced at Le Mans. With SRT Motorsports returning to full-time sports car racing competition this season in the American Le Mans Series (ALMS), the 24 Hours of Le Mans will again see the Viper GTS-R on track, as both the No. 53 and No. 93 will take the green flag.

Jeff Reece was part of the original Viper GTS-R race team that made the trek to Le Mans in 1996. He went back for five consecutive years and was part of three winning programs from 1998-2000. Reece, a Viper Vehicle Integration Engineer, will return again this year as will Dick Winkles, an SRT Powertrain Engineer, who has made a pair of trips to Le Mans, and has been part of two winning efforts in 1999 and 2000.

“We built up quite a reputation at Le Mans in the late 1990s,” said Reece. “Going back this year, everyone wants to have a good showing. We are putting that reputation on the line, so to speak with everything we have accomplished there in the past.”

The Viper GTS-R made its debut at Le Mans in 1996 in the GT1 class and completed all 24 hours of that race, finishing eighth in class and 10th overall. A total of four Vipers were in the field that year. In 1997, the team returned with another four-car contingent, this time competing in the GT2 class.

“We had some of the fastest cars on the track in 1997, but we had problems,” shared Reece. “Two different cars crashed so we lost a lot of time, and two other cars didn’t finish. That was disappointing to say the least, because that same year we were dominating the FIA GT Series and winning most of the races.”

A total of five Viper GTS-R race cars took to the grid in 1998 at Le Mans, scoring a class win in GT2, which marked the first win for the car in sport car racing’s biggest event. Vipers also placed second, fifth and seventh in class that year.

“Winning Le Mans was the one last big hurdle we had left to clear with the GTS-R program in 1998 and we were able to do it,” noted Reece. “It was a fantastic feeling. I’ll never forget what it feels like to be up for 40 hours straight after being sleep-deprived for most of the week to begin with and having a glass of champagne.”

Victory would again be taken by the Viper GTS-R in 1999 at Le Mans in the GTS class, to the tune of a 10th-place overall finish. Vipers would also cross the line second, third, fourth, fifth and sixth in class. Along with scoring a third consecutive class win in 2000, the Viper GTS-R scored its best-ever overall finish at Le Mans, taking seventh in the field of 48 cars. In the GTS class, Vipers also came home second, fifth and sixth.

Returning to Le Mans for the first time in over a decade, the team has been diligently preparing for the endurance race. The pair of Viper GTS-R race cars will hit the famed Circuit de la Sarthe for the first time on Sunday, June 9, for a test day. A second practice day is scheduled for Wednesday, June 19, with a night session of qualifying to follow that evening and a pair of qualifying rounds on Thursday, June 20. The final time the cars will hit the track prior to the 24 Hours of Le Mans will be on race morning, Saturday, June 22, for a warm-up session.

“A lot has changed since the last time we were there,” noted Winkles. “We obviously have a new car this year and the aerodynamics are very different and that’s very important over there. One of the disadvantages that we’ll have is that all of the cars we are competing against have been there the last couple of years, so they know the set-ups for their chassis, suspension and aero, while we’ll still be learning. That’s going to be tough for us, but anything can happen as long as you stay out there on the track.”

A field of 56 cars in four classes is entered for this year’s 24 Hours of Le Mans, representing 16 countries from around the world. The SRT Motorsports team will be one of six squads from the United States competing and will take to the track in the LMGTE Pro class. A number of teams that regularly race against the Viper GTS-R in the ALMS GT class will be in attendance.

“The competition is so tight right now,” noted Reece. “The cars are more evenly matched than ever. Part of that is the way the sanctioning body is running the race. They are trying to make everyone evenly matched and that makes for some exciting racing. It means you really have to optimize everything to stand a chance.”

That chance will come for the pair of SRT Viper GTS-R race cars on June 22 as the 81st edition of the 24 Hours of Le Mans takes the green flag.

No Bullshit Racing, Ljungbyhed

SRT GTS-R 2013

Snart riktigt färdig

Venom GT

Lamborghini, Ferrari och Koenigsegg må vara snabba, men de rår inte på Hennesseys Venom GT. Bilen är världens snabbaste produktionsbil och accelerationen tar inte slut förens vid 427,6 km/h.

Hennesseys Venom GT är i grunden en Lotus Elise – men självklart är den rejält modifierad för att kunna vara med och leka i det absoluta toppskiktet av fartmaskiner. Och den är onekligen snabb. I januari etablerade sig modellen som världens snabbaste produktionsbil när det kom till accelerationen 0-300 km/h. Guinness rekordbok klockade en snittid på 13,63 sekunder.

Den 9 februari stoltserade Venom GT med ytterligare ett ”rekord”. Nu var det topphastigheten bland produktionsbilar som gällde. Hastigheten uppmättes på United States Naval Air Station Lemoore i Kalifornien och blev oerhörda 427,6 km/h.

– En Veyron Super Sport klarade av 430 km/h, men Bugatti begränsar produktionsversionen till 415 km/h. Därför, med 427,6 km/h, är Venom GT den snabbaste produktionsbilen som går att köpa, sa John Hennessey efter fartuppvisningen.

En hästkraft per kilo

Venom GT hämtar kraften från en sjuliters V8 med dubbla turboaggregat. Motorn ger 1 244 hästkrafter och 1 566 Newtonmeter. Lägg till att alla dessa hästar bara har 1 244 kilo bil att flytta på, så är det lätt att förstå att det går att få upp farten snabbt. Är du sugen? Hennessey kommer bara att bygga 29 exemplar av sin rekordbil och priset för en Venom GT ligger på motsvarande 7,8 miljoner kronor.

Nu har Hennessey lagt ut en film från sin hissnande snabba ”rekordfärd”…

http://www.venomgt.com

http://www.hennesseyperformance.com

http://www.tunerschool.com

SPECIAL THANKS TO:

The United States Navy:

http://www.navy.com

Brian Smith, test driver:

http://www.full-lock.com

V8 Thunder Cars 3 & 4 Maj Ring Knutstorp...

Närmar sig...